Soil Vapor Intrusion Testing

VAPOR INTRUSION TESTING

SanAir’s Centek division has extensive experience sampling and analyzing a broad range of air contaminants including Volatile Organic Compounds (VOCs). We have worked throughout the United States with vapor intrusion testing.

Our instrumentation can be modified by our technical staff according to your project’s needs to achieve low detection limits while maintaining the highest quality data for your Vapor Intrusion projects. We work with large conglomerates, government agencies, as well as smaller private firms and homeowners.

Centek holds NELAC and ISO 17025:2017 (LAP-182993) certification to run EPA Method TO-15, as well as several other local, state and federal programs. Contact the laboratory for our most up to date certification information.

Volatile Organic Compounds Testing

VOLATILE ORGANIC COMPOUNDS

SanAir’s Centek division has extensive experience sampling and analyzing a broad range of air contaminants including Volatile Organic Compounds (VOCs). Using state-of-the-art, advanced GC/MS and cryo-focusing technology, we offer positive confirmation along with superior sensitivity.

Centek uses 400cc,1L and 1.4L summa canisters for sample collection. These vacuum canisters feature quick connect regulators that offer no tool/no power sampling systems, enabling our clients to nimble and efficient in the field without compromising our laboratory’s ability to deliver parts per million (ppm), parts per billion (ppb) and parts per trillion (ppt) detection limits. In addition to Centek’s TO-15 list, we can scan for more than 125,000 additional hazardous compounds within the air matrix using Tentatively Identified Compounds (TIC) analysis.

Centek holds NELAC and ISO 17025:2017 (LAP-182993) certification to run EPA Method TO-15, as well as several other local, state and federal programs. Contact the laboratory for our most up to date certification information.

BioGas Matrix Analysis Testing

RENEWABLE ENERGY

The age-old saying of “One man’s garbage…Is another’s mans Gold” is becoming true in the reclaiming of Biogas from landfill operations. While we still depend on fossil fuels as our primary energy resource, the use of newer and cheaper energy sources such as landfill gas is increasing throughout the world today.

The age-old saying of “One man’s garbage…Is another’s mans Gold” is becoming true in the reclaiming of Biogas from landfill operations. While we still depend on fossil fuels as our primary energy resource, the use of newer and cheaper energy sources such as landfill gas is increasing throughout the world today.

Biogas, and particularly landfill gas, or LFG, is usually heavily contaminated with VOCs (Volatile Organic Contaminants). VOC levels can exceed 1,000 ppmv, and are usually at least 50 ppmv, requiring removal by specialized treatment equipment so LFG can be used as a reliable fuel. Treatment systems for heavily contaminated biogas utilize media that is regenerated on a continuous basis to prevent siloxanes, halogenated VOCs, and other harmful VOCs from entering combustion equipment or being released to the atmosphere.

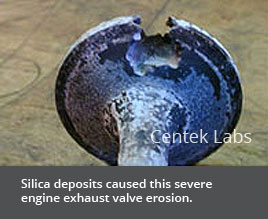

Organosilicons cause most of the damage to Internal Combustion (IC) engines, microturbines, boilers, and SCR catalysts. We measure the organosilicon content, major gas components (methane, nitrogen, oxygen, carbon monoxide & carbon dioxide), complete VOC (volatile organic contaminant) spectrum, plus organic and inorganic sulfur of your biogas. From this analysis, our biogas molecular scientists can determine the fouling potential (from silica formation) and treatability of your biogas.

Along with our industry partners, we can provide you with test results. We can develop a complete gas profile and determine the proper treatment processes needed to meet even the most stringent biogas specifications for use as a fuel. These treatment methods can include:

- Siloxane (and other organosilicons) Removal

- Moisture Removal

- Sulfur Removal

- Methane Content Upgrade

- System Maintenance

LEED® Indoor Air Quality Testing

LEED 4 IAQ AIR TESTING PROGRAM

Are You Ready for the New V4 IAQ Test?

TO ESTABLISH BETTER QUALITY INDOOR AIR IN THE BUILDING AFTER CONSTRUCTION AND DURING OCCUPANCY.

The New V4 requirements are as follows:

Air testing now worth (2 points)

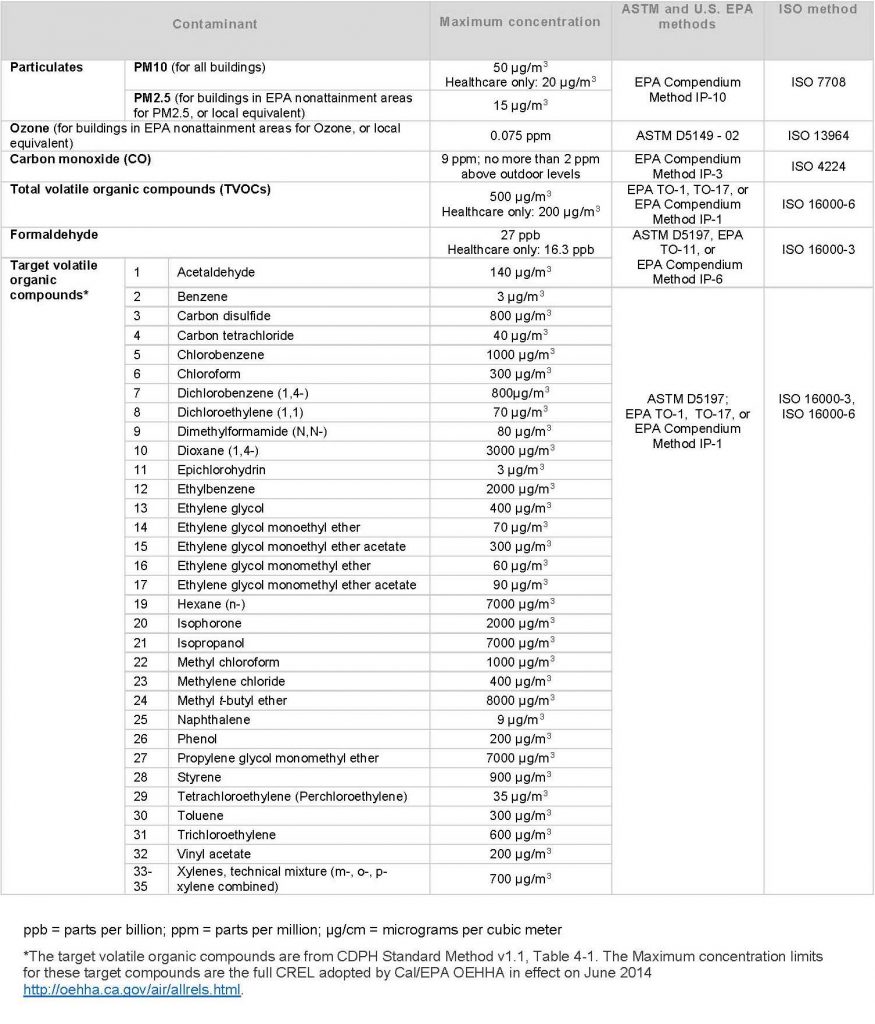

After construction ends and before occupancy, but under ventilation conditions typical for occupancy, conduct baseline IAQ testing using protocols consistent with the methods listed in Table 1 for all occupied spaces. Use current versions of ASTM standard methods, EPA compendium methods, or ISO methods, as indicated. Laboratories that conduct the tests for chemical analysis of formaldehyde and volatile organic compounds must be accredited under ISO/IEC 17025 for the test methods they use. Retail projects may conduct the testing within 14 days of occupancy.

Demonstrate that contaminants do not exceed the concentration levels listed in Table 1.

Table 1. Maximum concentration levels, by contaminant and testing method

Click Here for PDF Version

See our blog or call Russell Pellegrino at (315) 431-9730 for updates.

LEED 3.2 IAQ AIR TESTING PROGRAM

Per LEED® 2009 for New Construction and Major Renovations IEQ Credit 3.2: Construction Indoor Air Quality Plan—Before Occupancy OPTION 2. Air Testing

SIMPLE – COST-EFFECTIVE – SUSTAINABLE LEED® Air-Sampling and Analytical Program

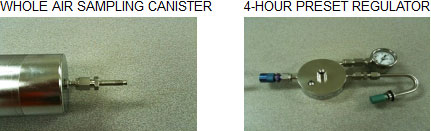

Upon researching air-sling programs available from other laboratories, the Centek Labs team of analysts and LEED® Certified Professionals aimed to utilize its unique capabilities to provide a program that is simple, cost-effective, and environmentally friendly. After thorough research, the Centek Labs team developed an air-sampling program using our specially treated whole air-sampling canisters and instrumentation while adhering to all requirements set for the by LEED® 2009 for New Construction and Major Renovations IEQ Credit 3.2: Construction Indoor Air Quality Plan—Before Occupancy OPTION 2. Air Testing.

MEDIA USED

1) 1L Silonite – Coated Whole Air Sampling Canister and 4-hour Preset Regulator

COMPOUNDS OF CONCERN ANALYZED (via US EPA Compendium) Through One Whole Air Sample

- TVOC (Total Volatile Organic Compounds) 500 ug/m3

- FORMALDEHYDE 27 ppb

- CO (Carbon Monoxide) 9 ppm

2) PM10 MONITOR

COMPOUNDS OF CONCERN ANALYZED (via US EPA Compendium) THROUGH PM10 MONITOR

- Particulate (PM10) 50 ug/m3

Centek Labs Sustainable Air Sampling Program is Simple

The Centek Labs Sustainable Air-Sampling Program uses less (yet more innovative) media and equipment. Media set up and break down requires no tools or power. Media setup time is one-third of the estimated setup time of other sampling programs.

Centek Media Set up and Breakdown description (pdf)

LEED IEQ Credit 3.2 Air Testing Sampling Instructions

Centek Labs reports include all compounds of concern and their associated contamination levels. Avoid the hassles of having to interpret separate reports for each compound of concern.

COST-EFFECTIVE SUSTAINABLE AIR SAMPLING PROGRAM

SAVINGS are made possible through our ALL IN ONE PRICING schedule. TIME IS MONEY, because of its simplicity, you will spend less time in the field. Our standard analytical turn around time is 5 business days. We offer rush turn around times as soon as same day. The faster the building owner can occupy, the more money they can make.